In the world of specialty chemicals, safety, efficiency, and product integrity are non-negotiable. A prominent chemical company in the Southeastern United States recently faced a significant challenge: unloading eight distinct flammable solvents from tank trucks while maintaining the highest safety standards and eliminating the risk of product cross-contamination. At the outset, the company’s objective was to explore using chemical hoses for bottom unloading and vapor capture. However, with SafeRack’s consultative approach to safety solutions, a more efficient and ergonomic alternative emerged: installing rigid pipe loading arms, complemented by safety breakaway couplings and dry-break disconnects.’

Bulk Chemical Specialist

“As subject matter expert, I’ll leverage my years of experience as your personal consultant throughout the project to ensure you get a world-class solution.”

Ray Evans – SafeRack Bulk Chemical Market Specialist

Project Objectives:

- Ensure Unparalleled Safety: The primary goal was to implement a system that guaranteed the utmost safety for both operators and valuable assets during the unloading process.

- Enhance Operational Efficiency: The project aimed to streamline the unloading process, making it more efficient and user-friendly.

- Prevent Product Cross-Contamination: The chemical company sought to eliminate the risk of product cross-contamination, a critical concern when dealing with multiple solvents.

Project Components:

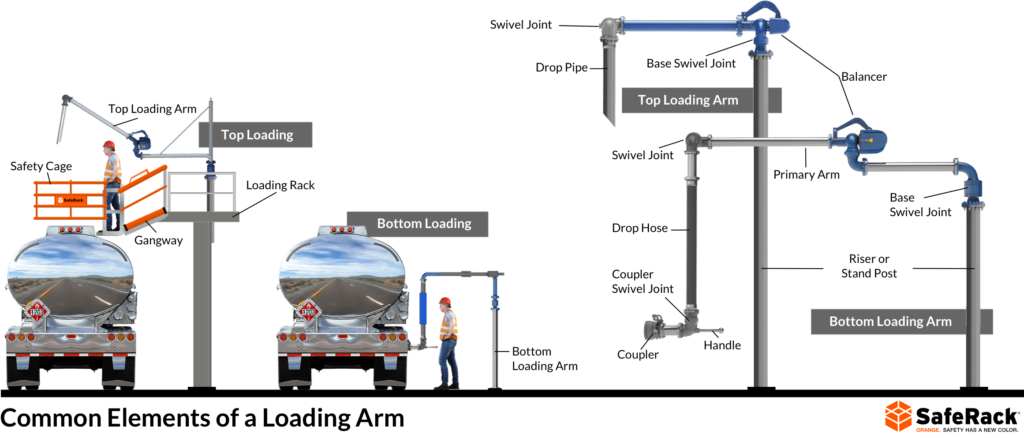

A. Rigid Pipe Loading Arms:

- Balance and Control: SafeRack’s loading arm solutions are meticulously balanced throughout their range of motion, allowing for precise control and ease of use.

- Asset and Operator Protection: These loading arms are designed to avoid contact with the ground, safeguarding valuable assets and operators alike.

- Ergonomic Design: SafeRack’s loading arms feature ergonomic design principles, enabling one-person operation and promoting worker safety and comfort.

- Seamless Positioning: Operators can effortlessly move the loading arms into position while preparing for the tanker connection, reducing downtime.

- Neat Storage: After unloading, the loading arms can be neatly parked, reducing clutter and minimizing tripping hazards.

SafeRack, North America’s leading provider of truck and railcar loading systems, is also the largest distributor for OPW and Emco Wheaton loading arms. Our expert coordination with engineers streamlines loading arm projects. Plus, we offer a vast range of swivel joints for complex liquid handling needs, ensuring greater productivity in your railcar loading systems. Choose SafeRack for efficiency and excellence.

B. Safety Breakaway Couplings:

- Emergency Disconnect: Safety breakaway couplings provide an automatic disconnect mechanism in case a driver accidentally pulls away while still connected, preventing dangerous spillage and ensuring safety in unexpected situations.

C. Dry-Break Disconnects with “Selectivity” Option:

- Precise Product Control: Dry-break couplers with a “selectivity” option allow for accurate control over product transfer, reducing the risk of unintended mixing or contamination.

Project Results:

The chemical company’s commitment to safety, efficiency, and product integrity culminated in the successful implementation of SafeRack’s solutions:

- Operator Safety: The installation of rigid pipe loading arms significantly enhanced operator safety during the unloading process, reducing the risk of accidents and injuries.

- Operational Efficiency: The streamlined unloading process, thanks to SafeRack’s loading arms, improved operational efficiency, reducing downtime and increasing overall productivity.

- Product Integrity: Dry-break disconnects with “selectivity” options effectively prevented product cross-contamination, ensuring the integrity of each solvent being unloaded.

- Customized Solutions: Collaborating with trusted fluid transfer channel partners, SafeRack designed double-sided stand posts that efficiently supported the new loading arms, minimizing the footprint at each unloading station.

This project profile highlights how SafeRack’s consultative approach and comprehensive safety solutions played a pivotal role in enhancing safety and efficiency while unloading flammable solvents. By implementing rigid pipe loading arms, safety breakaway couplings, and dry-break disconnects, the chemical company achieved its safety and efficiency goals and reduced the risk of product cross-contamination. SafeRack’s dedication to delivering tailored safety solutions makes it an invaluable partner for industries committed to safe and responsible chemical handling.